Rubber Rollers

Rubber Coated Roller & Pulley

For Various Types of Applications

Protect it with Rubber®

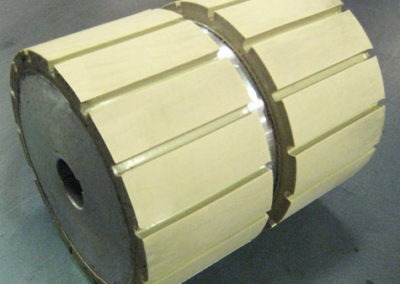

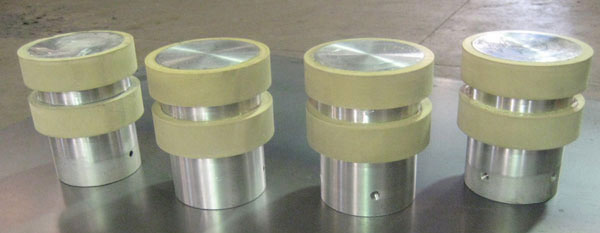

Whether you need a completely new roller or are recovering your existing core, Sioux Rubber & Urethane can accommodate almost any need and size up to 60” diameter and 20’ length. Most orders are ready to ship out in three days or less. Crowned and/or grooved roller rubber coating finishes are also available upon request.

Sioux Rubber & Urethane can apply an Endurawear® Rubber or Endurawear® Urethane coating, or lagging, to virtually any size pulley or roller. Our rubber lagging is vulcanized to the pulley, or roller, resulting in a bond that will not pull loose even under extreme conditions (unlike many glued-on materials). Sioux Rubber and Urethane can also strip and re-coat your existing rollers at our facility with quick turnaround times.

- Roller rubber coatings available from 0.063” and up in thickness

- Capable of covering rollers up to a 60” diameter and 20’ length

- Special materials or configurations available upon request

- Resurfacing existing rollers or pulleys with rubber or urethane compounds

- Quick turn around on all roller items

Our customers often come to us and ask for custom rubber coated rollers and pulleys to meet their needs. Many other companies lack the expertise to fulfill these requests, whether it’s a custom size or specific material. We take pride in offering our customers what they need most so they can continue their operations without further delay.

What Is a Rubber Roller?

A rubber roller is a machine composed of a metallic tube with a rubber layer. It is used in a variety of manufacturing processes. It helps to accomplish a wide range of mechanical functions in the furniture, food, plastic, and textile industries. It’s most commonly used for printing, steel and paper production, and roll-coating.

If you’re unsure whether a rubber roller is right for your application, don’t hesitate to contact our team. We can help determine how to create more efficiencies in your processes or functions by implementing roller rubber coatings or resurfacing your existing rollers with a different material.

Benefits of Rubber Rollers

Unlike other materials, rubber rollers are resistant to changing their shape after repeated use. They also absorb shocks well and resist wear and tear. Rubber rollers are fairly easy to replace and repair, making them perfect for the industrial services in which they are most commonly employed. With high-impact strength and abrasion resistance, rubber rollers are built to last.

Industrial processes often require repetitive motions, which can quickly wear out machinery parts made out of metal. The costs of repairing or replacing these parts can quickly add up and impact your bottom line. The time you have to invest can also slow down your operations and cause unexpected delays. Rubber rollers are cost-effective alternatives that perform consistently, whether it’s day one or day 100. There’s no need for constant maintenance or replacement, saving you valuable time and money in your operations.

Uses of Rubber Rollers

As mentioned, rubber rollers are primarily used in industrial settings. This includes conveyor belts during production times, as they are often valued for their high coefficient of friction. The furniture industry also uses rubber rollers for sanding and pressing operations. The plastic industry uses them to make laminates and film coatings. Textile industries employ them to bleach and dye fabrics. Rollers are used in the food industry for food packaging, while the leather industry uses them for treating their products. Lastly, the glass industry uses rubber rollers for the forming process.

Due to its versatile nature and ability to come in many different finishes, a rubber roller is a precious tool in many manufacturing industries! On top of having a high coefficient of friction, rubber rollers also have high-impact strength, shock absorption, and abrasion resistance. All of these are highly beneficial when it comes to consistent use.

Production deadlines are critical in the manufacturing industry, and it’s essential for machines to run smoothly at all times. Our roller rubber coatings are extremely durable, which ensures your operations aren’t slowed down by time-consuming repair jobs. The customization options also ensure your machines will perform efficiently and effectively to meet your unique needs.

Finishes Available:

- Grooved

- Smooth

- Diamond

- Herringbone

- Crowned

- Step crown

- Spiral

A variety of Endurawear® Rubber compounds are available to meet your specific service requirements. Even multi-layer roller rubber coating applications are available (example: a cushioning soft under-layer with harder rubber on the outside surface).

Our rubber rollers have been used in a wide range of industries so we can recommend a custom configuration that will provide the most benefits. We’ll ask the right questions to discover some of your biggest challenges, and we’ll make sure we find an exact solution that will last for years to come.

Contact Our Team Today

If you’re looking for high-quality rubber rollers for your production needs, contact Sioux Rubber & Urethane today! We’ll address your needs and provide a quote.

Together we’ll determine the right product and create more efficiencies in your industrial processes.

Rubber Coated Rollers & Pulleys

Crowned Roller

Roller 15-3/4″ Dia. x 16″ face covered with natural rubber and tapered to 13-3/4″ Dia.

Grooved Roller

Roller 3-1/2″ OD x 8″ face covered with white food grade neoprene rubber and a grooved pattern

Download the Sioux Rubber & Urethane Product Catalog

Are you interested in learning more about how our custom urethane products can extend the life of your equipment? Contact us to speak with a friendly representative and receive a quote. Download our product catalog now to get the complete overview of products and services and learn how your equipment can last longer.

Protect it with

Rubber®

Service and Quality

Contact our experienced sales and research staff and they will work with you to develop the right product or find the right coating for your specific needs. Over the last 40 years we have earned the reputation in the industry of being an on time supplier of high quality rubber and urethane products. Whether you are in the mining, aggregate, agricultural, chemical or manufacturing industry we can protect your equipment and machinery from abrasion, impact and corrosion thus reducing downtime, maintenance and repair cost. This will allow you to extend equipment life, increase productivity and decrease operating and maintenance costs.

Quality Rubber Products Are Ready For You

SiouxRubber © Copyright 2019